Warehouse automation and optimization (WAO)

Modern warehouse operations face unprecedented challenges in meeting the demands of e-commerce growth, labor constraints, and customer expectations for rapid delivery. Drawing from Amazon's extensive experience in operating over 150 million square feet of fulfillment center space globally, the Amazon Global Engineering team has developed proven approaches for warehouse automation and optimization. These insights, combined with AWS Cloud capabilities, form the foundation of the warehouse automation and optimization (WAO) offering from AWS Professional Services, providing customers with battle-tested solutions for their warehouse operations.

WAO uses multiple AWS services for physical facility design and simulation. Special cameras take images plus create dimensional data for 2D models of the facility that are fed through visualization GenAI services to transform into 3D, realistic models of operations. The three-dimensional models enable sophisticated scenario analysis by simulating various throughput calculations, thereby generating actionable insights for strategic decision-making. Real-time visualization of warehouse operations and KPIs can then be integrated with the model using AWS IoT Core to connect and sensors and automated systems throughout the facility. AWS IoT SiteWise creates a digital twin of the warehouse for monitoring and optimization. Amazon S3 and Amazon RDS store facility layouts, operational data, and simulation results. These simulation models validate design changes and predict operational impacts, for strategically laying out warehouses to maximize efficiency.

For automation and robotics integration, WAO employs AWS RoboMaker to develop, test, and deploy robotics applications, while AWS IoT Greengrass enables local compute and machine learning at the edge for automated guided vehicles (AGVs) and robotic picking systems. Amazon SageMaker AI powers ML models for demand forecasting, inventory optimization, and predictive maintenance. Real-time data processing is handled through Amazon Kinesis Data Streams and Amazon MSK, feeding into Amazon EMR for large-scale data processing. Amazon EventBridge orchestrates workflows between warehouse management systems, while AWS Step Functions manages complex automation sequences.

The solution's integration layer utilizes Amazon API Gateway and AWS AppSync to connect various warehouse systems and external applications. Security is maintained through AWS Identity and Access Management and AWS Security Hub, for proper access controls and compliance. Amazon CloudWatch and AWS X-Ray provide comprehensive monitoring and troubleshooting capabilities. The entire solution is deployed and managed using AWS CloudFormation and AWS Systems Manager, enabling consistent implementation across multiple facilities. This comprehensive technology stack, combined with expert advisory consulting from AWS Professional Services, delivers a modern, efficient warehouse operation that reflects Amazon's own journey in warehouse innovation and excellence.

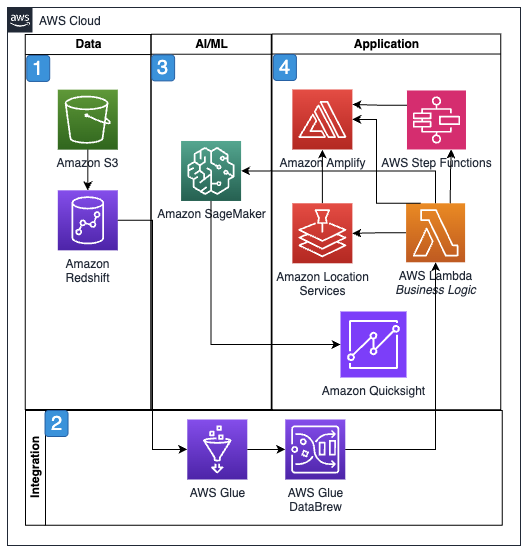

Reference architecture

Architecture description

-

Raw data is stored in Amazon SFormatted data is stored in Amazon RDS.

-

Amazon API Gateway provides endpoints for inbound data which is translated and loaded through AWS AppSync. Amazon Kinesis Firehose processes real-time data from IoT devices.

-

AWS IoT Core, AWS IoT SiteWise, and AWS IoT Greengrass provide the system for managing IoT devices. AWS RoboMaker provides the environment to build, test, and deploy robotics applications.

-

Amazon SageMaker AI provides AI/ML for measuring throughput and optimization recommendations. AWS Step Functions and Amazon EventBridge coordinate event driven process flows. AWS Lambda holds programming logic. Amazon QuickSight presents dashboards and metrics.

Architecture objectives

-

Physical design and simulation.

-

Automation of operational IoT workflows.

-

Data and analytics for warehouse operations.

-

Integration of IoT operations and warehouse systems.

Metrics

Based on the warehouse automation and optimization (WAO) scenario, five relevant metrics are:

-

Throughput efficiency:

-

Primary metric: Orders processed per hour compared to theoretical maximum

-

Supporting metrics:

-

Pick rate per automated system

-

Order fulfillment cycle time

-

Cross-dock processing speed – mainly applicable in retail operations where ocean containers are broken down for over the road transportation

-

Relevance: Directly measures the core operational efficiency of the automated warehouse

-

-

-

Robotics performance:

-

Primary metric: Robot utilization rate and efficiency

-

Supporting metrics:

-

AGV navigation accuracy

-

Robot picking success rate

-

Mean time between robotic system failures

-

Automated task completion rates

-

Relevance: Critical for measuring the effectiveness of the robotics integration using AWS RoboMaker

-

-

-

Digital twin accuracy:

-

Primary metric: Percentage variance between digital twin predictions and actual operations

-

Supporting metrics:

-

IoT sensor data accuracy

-

Simulation model precision

-

Real-time synchronization latency

-

Prediction accuracy of operational changes

-

Relevance: Essential for validating the AWS IoT SiteWise implementation and simulation reliability

-

-

-

Edge computing performance:

-

Primary metric: Edge processing latency for critical operations

-

Supporting metrics:

-

AWS IoT Greengrass processing times

-

Local ML inference speed

-

Edge-to-cloud synchronization efficiency

-

Resource utilization at edge locations

-

Relevance: Crucial for real-time operation of automated systems

-

-

-

System integration health:

-

Primary metric: End-to-end system integration uptime

-

Supporting metrics:

-

API response times

-

Inter-system communication latency

-

Event processing success rate

-

Integration error frequency

-

Relevance: Measures the effectiveness of the complex integration between various AWS services and warehouse systems

-

-

These metrics were selected because they:

-

Focus on critical aspects of warehouse automation and performance

-

Cover both physical and digital aspects of the solution

-

Align with key AWS services used in the implementation

-

Support measurement of operational excellence and efficiency

-

Enable proactive monitoring and optimization of the warehouse automation system