Business workflow

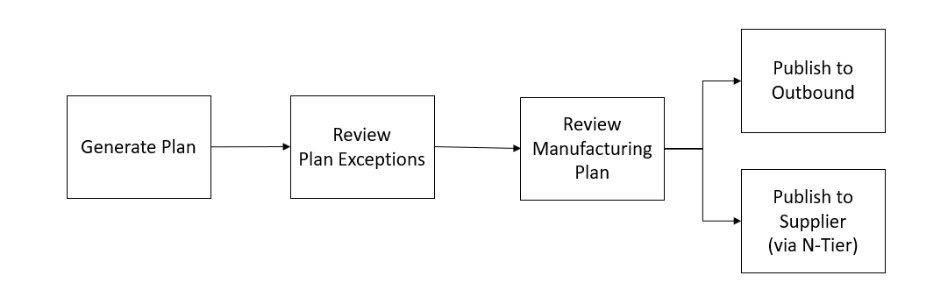

Supply Planning provides the following workflow to manage your manufacturing plans.

Generate plan – Supply Planning generates the manufacturing plan according to the configured schedule. The latest input data required to generate the plan is received from the AWS Supply Chain data lake. Supply Planning uses configuration data, transactional data, and plan settings to generate the manufacturing plan, which includes material, transfer, and production plans. The Manufacturing Plan is generated for the configured planning horizon in terms of the number of time periods. You can create plans with either daily or weekly details, and you can create them on a daily or weekly frequency. If multiple plans are created within the same planning cycle (daily or weekly), new plans will override the existing plans. Existing plans are versioned after a new plan is generated at the beginning of a new planning cycle (for example, a new week).

Review plan exceptions – Supply Planning generates plan exceptions for products or site combinations that do not have either required configuration data (lead time, sourcing schedule, and so on) or required transactional data, such as on-hand inventory. Planners can review exceptions and provide required data, and then they can rerun the plan to correct the issues and generate the supply plan for relevant product and site combinations.

Review manufacturing plan – Supply planners can review and manage material, transfer, and production plans by navigating to the Plan Overview, Plan Outputs, Supply Plan Details, and Supply Demand Pegging tabs in the AWS Supply Chain web application. The Supply Planning module generates Material Plan Change insights for products and sites where the required quantity deviation exceeds the configured threshold, relative to the most recent plan. Planners can configure the display of detailed inputs, such as forecasts, inventory levels, orders, and other relevant data that contribute to the calculation of the plan's output.

-

The Supply Plan Details page offers a comprehensive timeline view, displaying key metrics such as forecast, inventory, open orders, and planned supply. This allows planners to assess and adjust plans as needed.

-

The Supply Demand Pegging page provides a detailed list of all pegging records that link supply orders to their corresponding demand orders. Each pegging record includes information about the supply order (for example, on-hand inventory, purchase orders, planned purchase orders, planned manufacture orders, and planned transfer orders), the demand order (for example, sales orders, forecasted demands, and planned order demands), the pegged quantity, and the associated end demand. This view enables users to analyze how specific supply quantities are allocated to fulfill various demand orders, and vice versa.

Users can interact with the data by selecting any demand quantity to view all supply orders linked to it or selecting any supply quantity to see all demand orders tied to that supply. From this view, users can also navigate to the End Demand Pegging page by clicking the End Demand Product for a more consolidated overview of a specific end demand.

-

The End Demand Pegging page provides a comprehensive view of the entire pegging tree for a specific end demand, such as a sales order or forecast. It offers full visibility into all related supply and demand orders associated with the end demand, including planned transfer orders, planned manufacture orders, purchase orders, and intermediate demands. This view allows users to trace the entire supply chain flow, from the top-level demand to every linked supply and dependent demand orders, offering a clear insight into how supply orders are structured to meet customer or forecasted needs.

These views help users efficiently manage and track supply and demand allocation across the supply chain.

-

-

Planned order adjustments – Users can manually update the order quantity, order-by date, and expected delivery date for system-generated planned orders, including Planned Purchase Orders, Planned Transfer Orders, and Planned Production Orders. After making updates, users can mark these orders as Firmed to ensure they are preserved during planning runs. To run the plan in ad-hoc mode, users can choose Run Plan located in the top-right corner of the page. When the plan runs, the system retains all Firmed planned orders, recalculates planning measures on the Supply Plan Details page, and reflects any changes in upstream sites or bill of material (BOM) components in the updated plan output. In addition to modifying existing planned orders, users can create new Planned Transfer Orders directly from the Transfer Plan page by selecting Create New Transfer Order from the Action menu. After the ad-hoc plan run is complete, the system automatically synchronizes the updated planning data with the

supply_planandsupply_demand_peggingentities in the Data Lake. During the next scheduled planning run, the system will clear all previously Firmed planned orders and generate new ones based on the latest data inputs. Publish to outbound – Supply plans are published to the outbound Amazon S3 connector at the configured time scheduled under Plan Settings. You can integrate these plans into your ERP, purchasing, or production planning systems for execution.

Publish to N-Tier visibility – Material plans can optionally be published to the suppliers through N-Tier visibility. Material plans are published to N-Tier visibility based on the schedule that's configured under Plan Settings. N-Tier visibility further publishes the material plan to onboarded suppliers based on collaboration settings.